No products

RailCore ®

-

Self-Centering Thin Material Vice for Fiber Lasers

Self-Centering Thin Material Vice for...

$150.00 $175.00

Viewed products

-

7075 High temperature...

Full metal, high temperature, Z axis...

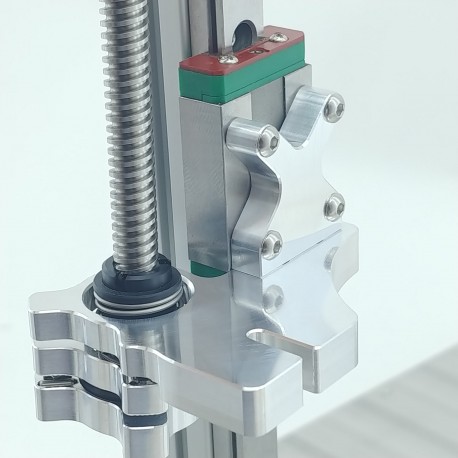

7075 High temperature Z axis yoke magnetic compensator

Full metal, high temperature, Z axis magnetic compensators for the Railcore II ZL & ZLT series of printers.

Made from high strength 7075 T6 aluminum.

This product is milled upon ordering.

Once ordered, please allow 4-5 working days prior to shipping.

More info

This product is milled upon ordering.

Once ordered, please allow 4-5 working days prior to shipping.

This full metal, high temperature, Z axis magnetic compensator replaces your existing Railcore Z axis assembly (yoke) and compensates for errors that are introduced by a bent or warped lead screw (lead screw induced Z banding). This product adds magnetic compensation for lead screw wobble while minimizing the loss of Z height. This product reduces the ability of the lead screw to impart artifacts to the build platform by compensating for warped or mildly miss-aligned lead screw in a high temperature printing environment (up to 150 deg C). All milled pieces are made out of high strength 7075 T6 aluminum. We have leveraged the properties of 7075 aluminum to allow us to more freedom in the design aesthetic while still maintaining the needed strength in our parts.

This product is inspired by several sources including the HevORT wobble rings and its many derivatives.

Each magnetic compensation set consists of 12 milled 7075 pieces; for each of the 3 axes, there is a top / yoke piece, a middle piece, a bottom piece, and a Z axis yoke riser, also included are high strength / high temperature neodymium magnets, metal rods, and bearing balls. The top, middle and bottom pieces will come with with pre-installed high temperature magnets (up to 150 deg C) and metal rods and are ready to install onto your printer. We also include M4 16mm 12.9 alloy steel socket head cap screws (black, uses a 3mm hex tool, not included) for mounting the Z axis yoke riser to the top / yoke piece. See the "optional" section below for additional low profile screw choices available for purchase. This product ONLY works for a configuration where the lead screw nuts are mounted below the bed, however it is fully compatible with a flipped Z configuration.

The top piece replaces your current Z axis assemble (yoke) and the lead screw nut fits through its center hole. The center hole of this top / yoke piece has been enlarged to allow this product to compensate for a much larger range of motion (wobble). The bottom piece contains 4 M3 form threaded holes and 4 M3 pass thru holes on the flange so they are compatible with either threaded or non-threaded lead screw nuts. The bottom piece will bolt to the bottom of the lead screw nut with the included 8mm button head screws. The top and bottom pieces will "sandwich" the middle piece (that surrounds your lead screw nut). The embedded magnets, rods, and ball bearings on each piece provide the magnetic compensation action.

The middle and top pieces are uniquely designed to encase your lead screw nut and since it will protrude out of the top of the top piece of this assembly, the total loss of Z height when using this product is only 14mm. Where your Z loss would be 27-29mm (depending on the brand of anti-backlash lead screw nut used) using a bottom mounted lead screw nut alone. Even though the lead screw nut is mounted below the bed, the unique design of this product, means that you are actually gaining back previously lost Z height when using this product vs. using a bottom mounted lead screw nut alone.

Please note: The pieces of each unit are designed to fit both the Zyltech and LDO brand, small, Delrin anti-backlash lead screw nuts with either threaded or non-threaded mounting holes. This product is also compatible with any small brass or Delrin (regular or anti backlash) lead screw nuts with a 16mm bolt pattern configuration and 22mm flange diameter. Please note that this product is not compatible with large Delrin nuts (those with a 30mm flange).

The unique design of this product does not require any lubrication and naturally has very low friction (due to minimal contact area between the ball bearings and metal rods). The use of ball bearings and metal rods allows only lateral movement while prohibiting rotational movement entirely. This ensures that this product does not induce any additional backlash into the system during high speed (Z-axis) maneuvers. All parts of this product are made of metal, and are ideal for a high temperature environment (up to 150 deg C) and there are no breakable or melt-able parts.

Please note: Normal lead screw lubrication is still required.

Each high temp magnetic compensator set includes:

x3 Z axis yoke riser

x3 top (yoke) piece (comes with magnets and metal rods fully installed)

x3 middle piece (comes with magnets and metal rods fully installed)

x3 bottom piece (comes with magnets and metal rods fully installed)

x15 ball bearings (4 per axis + 3 extra, in case of loss...they are tiny little buggers)

x12 M3 8mm button head screws (to mount lead screw nut to the bottom piece)

x6 M4 16mm 12.9 alloy steel socket head cap screws (black, uses a 3mm hex tool, not included)

Compatibility:

These magnetic compensator units are designed to fit the RailCore II series of printers. This product ONLY works for a configuration where the lead screw nuts are mounted below the bed, however it is fully compatible with a flipped Z configuration.

Optional:

If you are interested you may also purchase low profile M4 16mm 12.9 alloy steel, zinc coated, socket head cap screws here. These low profile zinc coated screws not only match the shiny aluminum finish of the parts, but they also sit almost flush to provide a sleeker look to your printer. We have found that these provide a cleaner look when using the flipped yoke configuration where these screws are visible.

Coming soon:

Instructions tab

Reviews

This solution is excellent

Easy to assemble in both configurations (up or down). Best Z insulation I have ever tested. (I have tested first and second generations and this is definitively better)