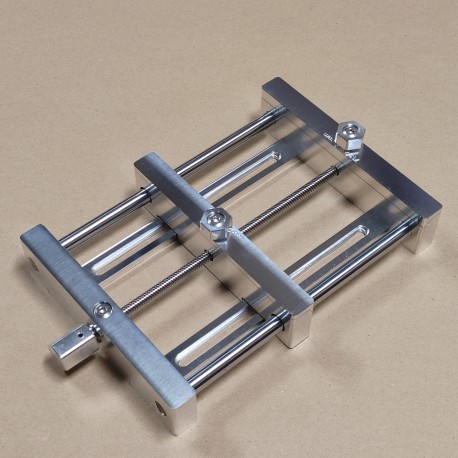

The lead screw locking collar is housed within a recess, creating a flush end and streamlined design, while thrust bearings at both ends ensure smooth operation. The opposite end is secured by the vice adjustment knob, and the vice is further enhanced with 12 mm guide rods and Igus Drylin linear bearings for improved performance

Cart

0

Product

Products

(empty)

No products

To be determined

Shipping

$0.00

Total

Product successfully added to your shopping cart

Quantity

Total

There are 0 items in your cart.

There is 1 item in your cart.

Total products

Total shipping

To be determined

Total

Fiber Laser Accessories

-

Standard Thin Material Vice for Fiber Lasers

Standard Thin Material Vice for Fiber...

$125.00 $150.00

Viewed products

-

Standard Thin Material...

Standard Thin Material Vice for Fiber...

Standard Thin Material Vice for Fiber Lasers

Standard Thin Material Vice for Fiber Lasers

The Standard Thin Material Vice offers a simple, reliable clamping solution with one fixed and one moving jaw. Made from durable 6061 aluminum, it provides smooth operation and easy adjustment for secure material holding. Ideal for traditional setups, it ensures precise cuts and engravings with lasting reliability.

- Write a review

Subscribe To When In Stock

You have successfully subscribed to this product

close

This product is milled on demand . Please allow up to 10 business days for processing before it is shipped

No stock is held

Standard Single Moving Jaw Thin Material Vice for Fiber Lasers

Take your fiber laser cutting and engraving to the next level with the Standard Single Moving Jaw Thin Material Vice—a precision-engineered solution designed for professionals and hobbyists alike. This vice features a single moving jaw mechanism, offering reliable and stable clamping for a wide variety of materials. Unlike a self-centering vice, this design requires manual adjustment for each new piece of stock, but provides exceptional control and ease of use for users who prefer to make those adjustments.

We also offer a Self-Centering version of this vice here.

Built with durability, ease of use, and ascetics in mind, the vice boasts a robust aluminum construction, precision linear bearings, and spring-loaded jaws for smooth operation. Whether you're engraving intricate designs or cutting materials with tight tolerances, this tool enhances accuracy and ensures a secure grip on your material during every project.

The vice is thoughtfully designed to meet the needs of specialized tasks. Removable clamping jaws enable coin engraving and other niche applications, while mounting slots ensure seamless integration into your laser setup. With a generous work area of over 165 mm (6.5 in) square, this tool provides ample space for your laser projects, making it an indispensable addition to any laser workspace.

Key Specifications

- Material Capacity: Holds materials up to 190 mm (7.5 in) x 180 mm (7 in) square and 5 mm thick, providing ample space for a wide range of projects

- Overall Dimensions: 282 mm x 180 mm (11.10 in x 7.09 in)

-

Mounting Flexibility: Equipped with four mounting slots, spaced 100 mm apart (the standard for most laser work tables), that allow for easy and precise positioning. These slots provide an 85 mm range of adjustment, giving you complete flexibility to position the vice exactly where you need it for optimal setup

- 4 low-profile M6 mounting screws are included

-

Single Moving Jaw Mechanism:

-

- The vice adjustment knob features an attractive and ergonomic design, allowing for easy adjustment by hand or with a 21mm socket/extension. This design is specifically crafted for convenient access to the knob, whether on or off the laser work surface. We recommend against using the socket/extension to tighten the vice jaws

- Once positioned, a single low-profile screw can easily lock the jaws in place (with a 4 mm Allen wrench). Please note that locking is generally not required for routine use

- Each jaw features a 5 mm deep by 5 mm wide L-shaped ledge designed to help accurately position and align the material for precise work

- Each jaw is paired with a corresponding L-shaped locking plate, which fits securely atop the jaw and locks the material in place. The grip of the locking plate can be easily adjusted with a single knob, ensuring the material is held securely during cutting or engraving

- The locking plate knob is designed for easy tightening, either by hand or using an (4 mm) Allen wrench and does not interfere with the laserable area

- The spring-loaded locking plate makes it simple to insert new stock and slide out finished material

- Coin Holding Capability and Fixture Support:

- Conveniently hidden underneath the locking plate are eight tapped holes in each jaw, designed to offer precise positioning for coin engraving or similar tasks

- The 8 included coin-holding screws fit into the tapped holes and project only 1.8 mm high, allowing for edge-to-edge coin engraving

- The width between each coin-holding screws is adjustable from 18 mm to 72 mm in 9 mm increments, allowing the vice to securely hold a single coin of almost any size or up to two 40 mm coins

- When not in use, the coin-holding screws can remain securely in the jaws, while the locking plates with recessed areas cover and protect them

- For added convenience, the locking plate springs are securely held in place by magnets within their recesses, preventing their loss when the locking plates are not in use during coin engraving. The springs can be removed easily, if desired

- Construction: Made from 6061 aluminum with precision linear bearings and 12 mm guide rods for smooth operation

- Includes the following:

- x1 Standard single jaw vice

- x4 M6 low profile mounting screws

- x8 Coin holding screws

Made in the USA

Proudly crafted in our home shop at 713Maker.com, ensuring the highest standards of quality and care

Be the first to write your review!